MetalKraft Industries Inc.

MetalKraft Industries Inc. is a family owned and operated company dedicated to providing a high level of customer satisfaction. Since 1983, MetalKraft has maintained its mission to offer great customer service by using the best business practices, coupled with leading process technologies.

We offer integrated computerized manufacturing process that enable us to be efficient throughout the ordering, production and shipping process. Our commitment to innovation allows us to offer “job shop” service, with the added benefit of high volume capacity. Our modern 50,000 sq. ft. plant is located in Wellsboro, PA.

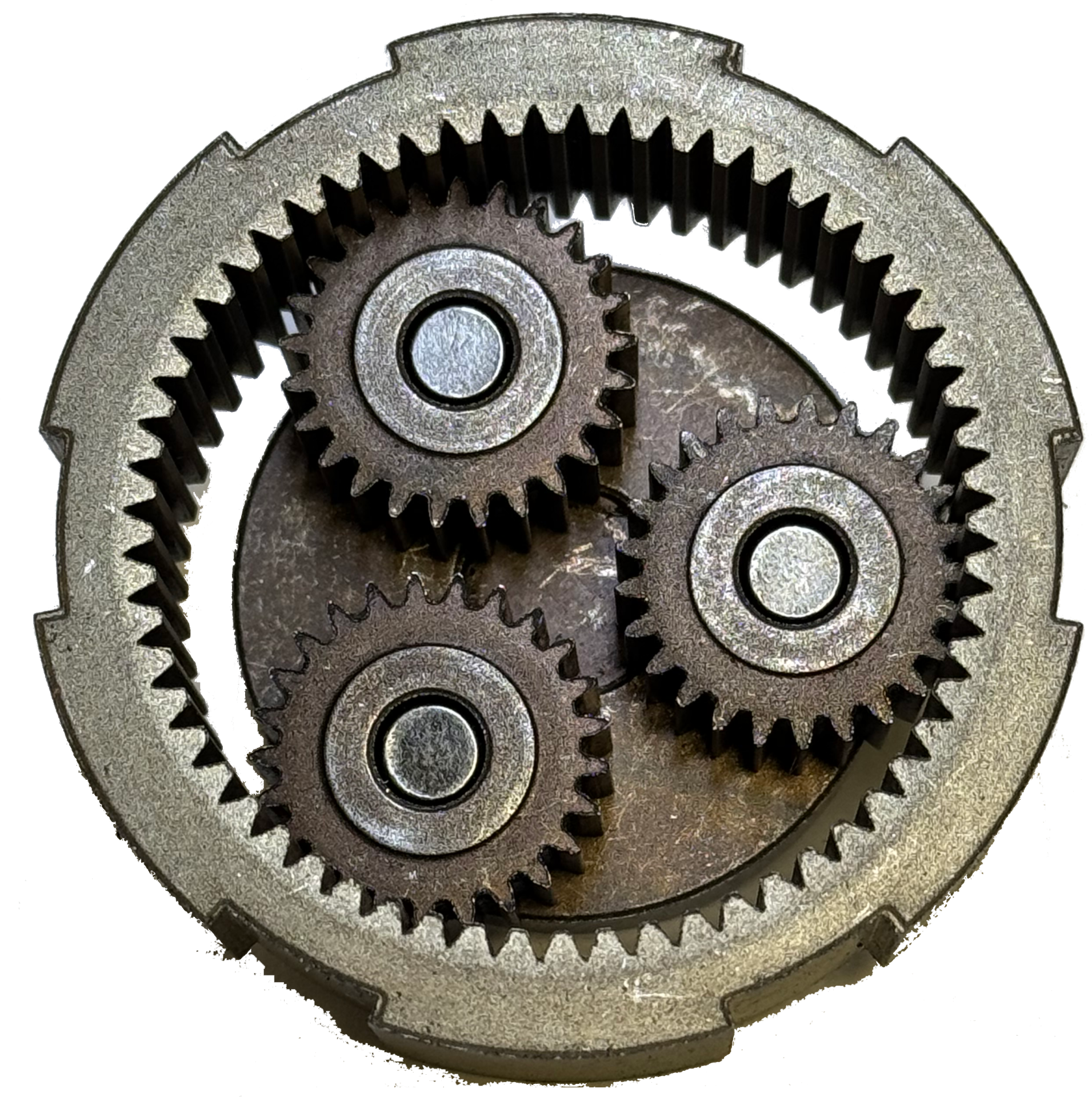

MetalKraft has been a premier supplier of powdered metal components since 1983. Our state of the art technology gives us the competitive edge, ensuring quality components at competitive prices.

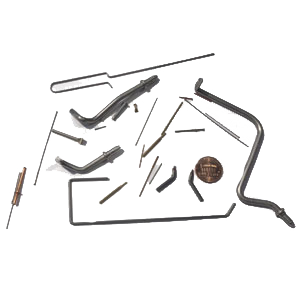

Our Cold Form Division has the capability to manufacture a wide variety of products from wire formed, cold headed, stamped, CNC screw machine, to pointing and more.

about the company

The MetalKraft Edge

Modern production technology can achieve a wide range of powder metal densities, so steel, stainless steel or bronze parts can now be used in an increasing number of applications. For you, this means exceptional quality at an exceptional cost.

The MetalKraft Edge Gives You

Product Quality Index

Energy Generation