The MetalKraft Process Can Make You a Better Contender in Your Industry

MetalKraft uses superior integrated computerized manufacturing systems so we are more efficient throughout the ordering, production and just-in-time shipping process. Our efficiency means you are more efficient. And better efficiencies translate into better profits. Our commitment to innovation allows us to offer “job shop” service, with the added benefit of high-volume capacity. Our modern 50,000 sq. ft. plant is located in Wellsboro, PA.

You’ll benefit from MetalKraft’s

Value-Added Individualized Process

Exceptional Customer Service

Cost- and Time- Saving Efficiencies

Innovation that finds you just what you need

The Smart Science Powering our Powder Metallurgy Process

MetalKraft uses a revolutionary highly developed method to manufacture precision metal parts so you get the best parts at the best price with the quickest possible delivery. The process involves mixing elemental or alloy powders, which are then compacted in a die. The resulting shape is sintered in an atmosphere-controlled furnace to convert mechanical bonds into metallurgical bonds. Our process is “chip-less” process, and the Power Metal uses roughly 97% of the starting material in the finished part, again a cost efficiency that helps you.

Your MetalKraft Advantage

Modern production technology can achieve a wide range of powder metal densities, so steel, stainless steel or bronze parts can now be used in an increasing number of applications. For you, this means exceptional quality at an exceptional cost. Consider these advantages of the MetalKraft powder metal process:

The Three-Step Process

Mixing

Elemental, partially alloyed or pre-alloyed metal powders are first blended with lubricants to produce a homogeneous mixture.

Compacting

A controlled amount of a mixed powder is gravity fed into a precision die and then compacted. Compaction occurs at room temperature, at a pressure range of 25-50 tons per square inch. Compacting the loose powder produces a “green compact” which, with conventional pressing techniques, has the size and shape of the finished part when ejected from the press. Green compacts have sufficient strength for in-process handling. Typical compaction techniques use rigid dies, set into mechanical or hydraulic presses.

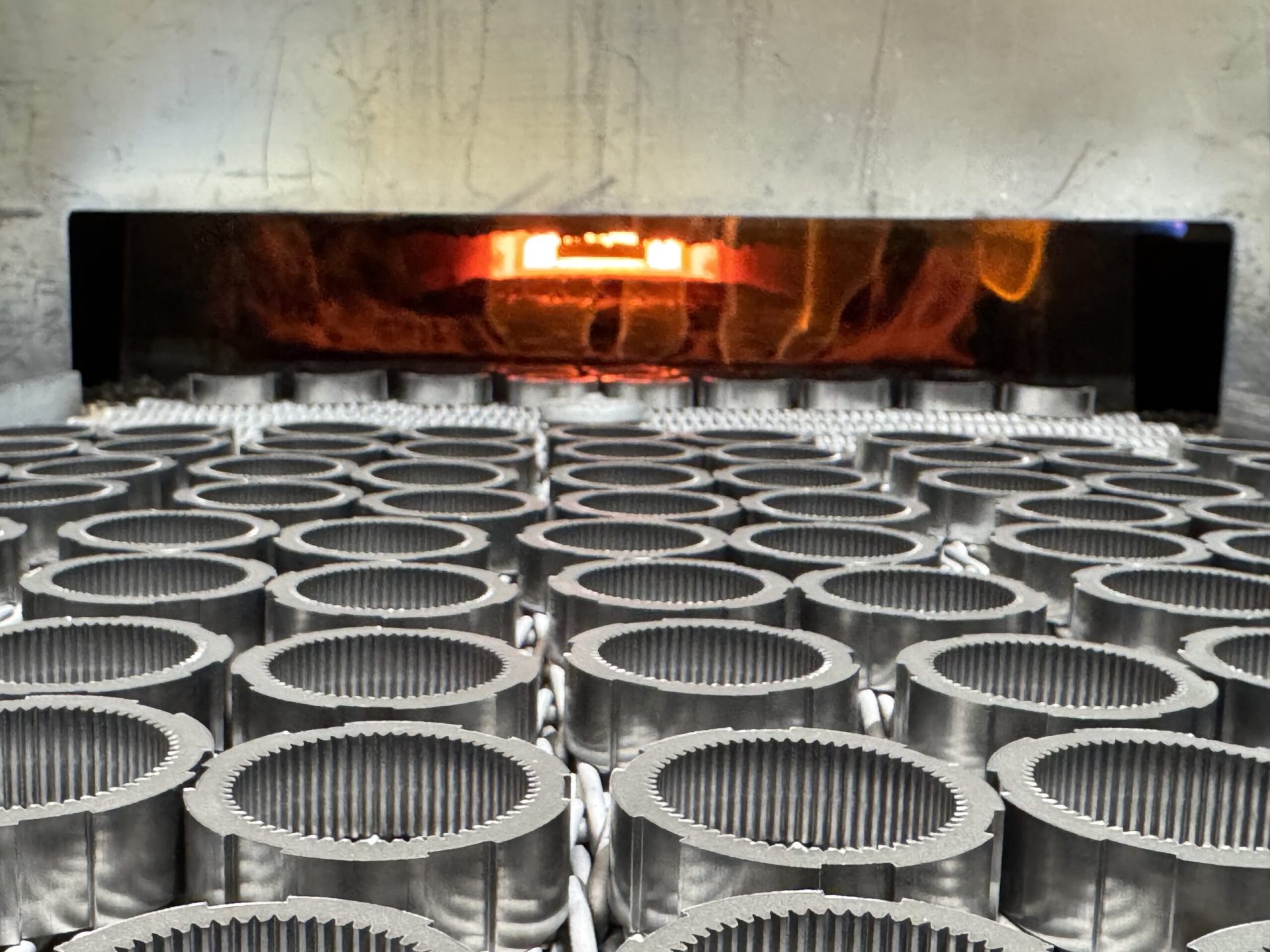

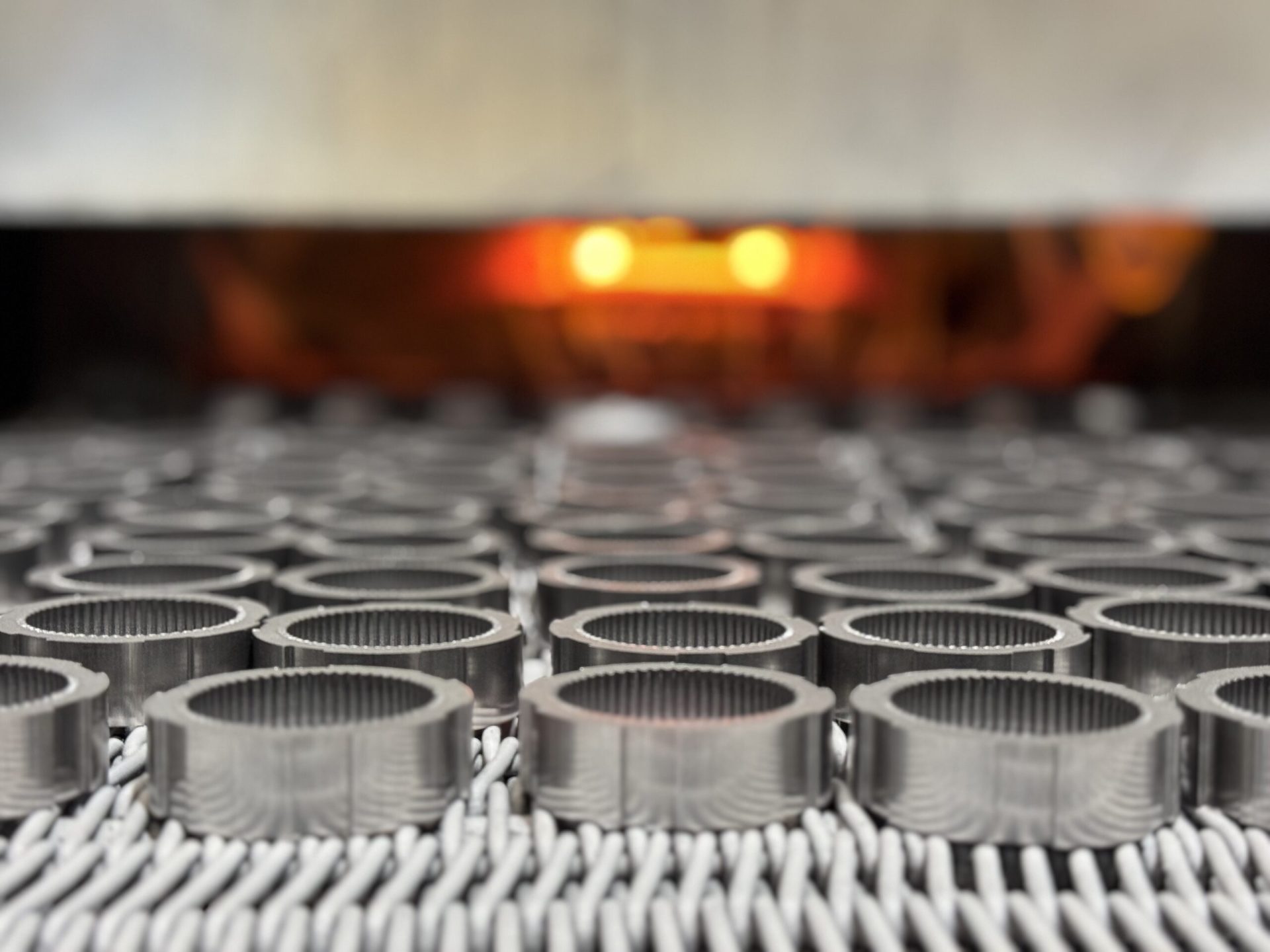

Sintering

Typically, the “green compact” is placed on a mesh belt which then moves slowly through a controlled atmosphere furnace. The parts are heated below the melting point of the base metal, held at the sintering temperature, then cooled. Basically a solid state process, sintering transforms compacted mechanical bonds between powder particles into metallurgical bonds. Typical sintering temperatures for ferrous based metals range from 2050- 2100 degrees F. Standard cycle times range from 2-3 hours.